What is the difference between hot melt adhesive and thermoset adhesive?

Many people who do not know much about adhesives do not know the difference between thermoset adhesives and thermoplastic adhesives. There are essential differences between these two categories of adhesive products, and because of this difference, yes they are in There are great differences in the way and scope of application. So what is the difference between thermoset adhesives and thermoplastic adhesives? Here is a brief introduction to you.

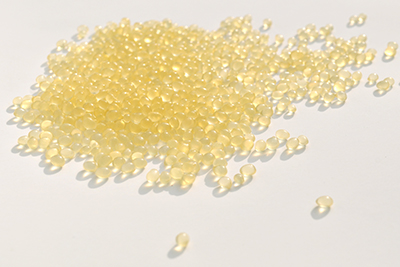

Hot melt adhesive is a thermoplastic adhesive. We know that many adhesives need to be heated during the bonding process. For hot melt adhesive, heating is to melt it. Because the hot melt adhesive is in a solid state at room temperature, only by heating, the hot melt adhesive can be melted into a liquid state and bonded on the surface of the adherend.

Thermosetting adhesives also need to be heated during sizing, because under certain temperature conditions, the chemical substances in the thermosetting adhesive components will speed up the chemical reaction and rapidly change from a linear molecular structure to a network-like cross-linked structure. Because of the chemical reaction that occurs throughout the process, thermoset adhesives are often referred to as reactive adhesives.

Hot melt adhesives are heated and melted, while thermosetting adhesives are heated and cured. Whether it is hot melt adhesive or thermosetting adhesive, they have their advantages and disadvantages, and they have a very wide range of applications in their respective fields. Hot melt adhesives are more efficient, and because they are solid at room temperature, they are cleaner and more environmentally friendly.

WinLong is a hot melt glue manufacturer, if you would like to learn more, please contact the adhesive experts at internetwoodglue.com. We have served customers in dozens of industries and can meet all your adhesive needs