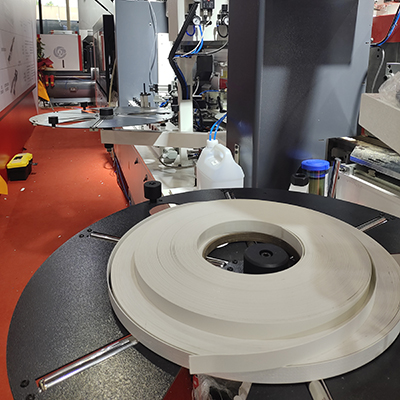

If you want to paste the edge banding, you can directly use the hot melt edge banding adhesive to paste the edge banding. It itself belongs to a type of hot melt adhesive. The shape looks like particles. There are two main colors, one is yellow, and the other is pure white, which can be selected according to needs.

Hot melt edge sealing adhesives have relatively strong adhesion, and there are three different types. Divided by temperature, there are low temperature, medium temperature and high temperature hot melt adhesives, of which high temperature has the highest adhesion, followed by medium and low temperature. At the same time, when the edge is processed, a fully automatic linear edge banding machine is also required. When working with high temperature hot melt adhesives, the temperature can generally be as high as 200°C.

Second, how to seal the edge

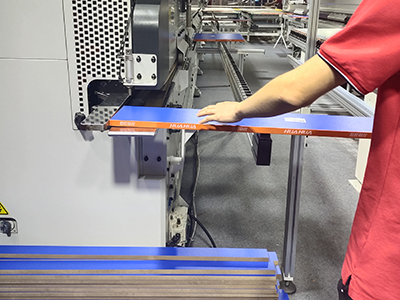

1. Glue edge sealing

It mainly uses glue to adhere the edge sealing materials, and the commonly used glues are mainly three kinds of all-purpose glue, hot melt glue and white latex.

2. U-shaped buckle

That is, there is a U-shaped buckle on the edge band, which can be directly buckled on the cabinet without glue when used.

Precautions for edge sealing

1. The indoor temperature should not be lower than 18°C during edge sealing.

2. To remove impurities from the edge of the sheet.

3. The glue on the edge should be well controlled.