Introduction:

Flat lamination is a widely used technique in various industries, offering a versatile solution for enhancing the appearance and durability of surfaces. From furniture manufacturing to interior design and automotive applications, flat lamination plays a crucial role in achieving high-quality finishes. In this article, we will delve into the concept of flat lamination, explore the lamination process, and highlight its diverse applications.

What is Flat Lamination?

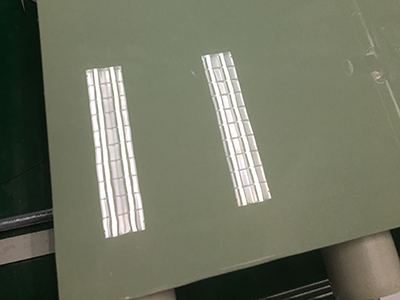

Flat lamination refers to the process of bonding a decorative or protective layer onto a flat substrate. It involves applying an adhesive between the substrate and the laminating material, such as paper, vinyl, fabric, or thermoplastic films. The adhesive creates a strong bond, securing the laminating material to the substrate and providing a smooth, finished surface.

The Flat Lamination Process:

The process of flat lamination typically involves the following steps:

Surface Preparation: The substrate surface is cleaned and prepared to ensure proper adhesion. It may involve sanding, cleaning, and applying a primer or adhesive promoter, depending on the specific materials used.

Adhesive Application: A suitable adhesive is applied to either the substrate or the laminating material. The adhesive choice depends on the materials involved and the desired bond strength.

Laminating Material Placement: The laminating material is carefully positioned onto the adhesive-coated substrate. Proper alignment and smooth application are crucial to achieve a seamless and aesthetically pleasing finish.

Pressure Application: Pressure is applied to the laminating material and substrate, ensuring a strong bond and even distribution of the adhesive. This can be done using rollers, press machines, or vacuum presses.

Trimming and Finishing: Excess laminating material is trimmed, and the edges are carefully finished for a clean and professional look. This step ensures that the laminated surface blends seamlessly with the substrate.

Applications of Flat Lamination:

Flat lamination finds a wide range of applications across various industries, including:

Furniture Manufacturing: Flat lamination is extensively used in the furniture industry for enhancing the aesthetics and durability of surfaces. It allows for the application of decorative patterns, wood grain textures, or solid colors onto furniture components such as tabletops, cabinet doors, and panels.

Interior Design: Flat lamination is popular for interior design applications, enabling the creation of visually appealing surfaces for walls, ceilings, doors, and countertops. It offers a cost-effective way to achieve a desired look and feel, ranging from high-gloss finishes to textured or patterned designs.

Automotive Industry: Flat lamination is utilized in automotive interiors for enhancing the appearance and functionality of dashboards, door panels, and trims. It provides a protective layer against wear and tear, UV radiation, and chemical exposure, while offering customizable design options.

Retail Fixtures and Displays: Flat lamination is used in the production of retail fixtures, such as shelving, displays, and point-of-sale materials. It helps create eye-catching surfaces that are durable and resistant to scratches, ensuring a visually appealing and long-lasting presentation.

Conclusion:

Flat lamination is a versatile process that allows for the application of decorative or protective layers onto flat substrates. It offers a range of benefits, including enhanced aesthetics, improved durability, and customization options. With its applications spanning furniture manufacturing, interior design, automotive, and retail industries, flat lamination continues to play a significant role in achieving visually appealing and functional surfaces. By understanding the concept and process of flat lamination, industries can leverage this technique to enhance their products’ quality and appeal.