It is generally believed that the cabinets made by woodworking are space-saving and durable, but the disadvantage is that they are poor in aesthetics. Especially if the edge banding is not handled well, it will not only be ugly but also affect normal use. If you plan to let the woodworker hit the cabinet, then you must pay attention to the edge banding.

What materials are used for edge banding?

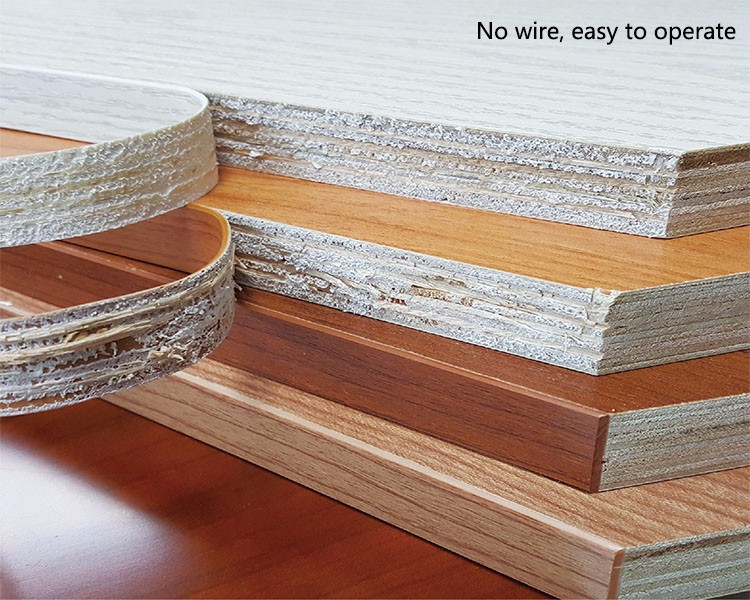

1. Wooden edge banding, such as birch, oak, maple, cherry, etc. Many middle and high-end homes will use this kind of edge sealing, and the price is high.

2. PVC edge banding, made of polypropylene or polyvinyl chloride, can be processed into wood grain, plain color and double color. Used for middle and low-end furniture, it is relatively soft and easy to construct. Many woodworkers will use this material for edge sealing when making furniture. The disadvantage is that it is not easy to bond, and it is easy to degumming later.

3. Melamine edge banding is based on paper printed with various wood grains, flowers, leather, and marble patterns, and then impregnated with modified melamine resin to form a paper edge banding.

There are also metal edge strips, and the usage rate is not very high.

What are the ways of edge sealing?

The cabinets made by carpenters in home decoration, especially the paint-free boards, generally need to be edge-banded. In addition to the materials we introduced above, the edge banding method is also an important part related to the quality of the finished product. At present, there are two kinds of manual edge sealing methods that are used: glue sealing and U-shaped buckle edge.

1. Seal the edge with glue

There are mainly three types of glue for edge sealing: universal glue, hot melt glue, and white latex. The best effect is hot melt glue.

2. U-shaped buckle edge

That is, there are U-shaped buckle edges on both sides of the edge banding, which can be directly buckled on the cut wardrobe board, which is convenient and practical, but the rubber-sealed edge banding is better in terms of durability.

In addition, we need to understand that the edge banding of the machine is more firm, beautiful and smooth. This is also an advantage of custom furniture.

It is better to use PVC material for cabinets made by home-made carpenters, which have more designs and colors and are more durable. At the same time, using glue seals will be more durable. Of course, you must buy good glue. Here, Mr. Gu will tell you a little trick. If the glue of your home’s edge banding is opened, you can heat it with an electric iron after applying the glue.