Introduction:

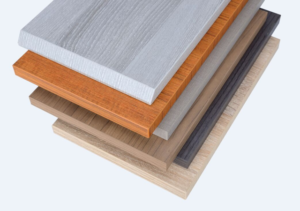

When it comes to PVC edge banding, choosing the right adhesive is crucial to ensure a secure and seamless bond. The adhesive selection plays a significant role in the longevity and visual appeal of the finished product. In this article, we will explore the options and reveal the best glue for PVC edge banding, helping you achieve exceptional results in your woodworking projects.

Hot melt adhesive is a popular choice for PVC edge banding due to its fast bonding and excellent adhesion properties.

It is applied in a molten state using a hot melt edgebander, which ensures precise and efficient application.

Hot melt adhesives create a strong and durable bond, capable of withstanding various environmental factors and everyday use.

Solvent-Based Adhesive:

Solvent-based adhesives are known for their high initial tack and strong bonding capabilities.

They contain volatile solvents that evaporate during the curing process, leaving behind a robust adhesive layer.

Solvent-based adhesives offer good adhesion to PVC and are suitable for both manual and machine application.

Water-Based Adhesive:

Water-based adhesives are environmentally friendly alternatives that have gained popularity in recent years.

They offer low VOC (volatile organic compound) emissions and are safer to handle compared to solvent-based options.

Water-based adhesives provide reliable adhesion to PVC edge banding and offer good heat resistance.

Contact Adhesive:

Contact adhesives are widely used for PVC edge banding due to their high bond strength and versatility.

They are applied to both the PVC edge banding and the substrate, allowed to dry, and then pressed together to form a bond.

Contact adhesives provide an instant and strong bond, allowing for precise alignment during the assembly process.

Factors to Consider:

Compatibility: Ensure that the chosen adhesive is specifically formulated for bonding PVC materials.

Application Method: Consider the available application methods, such as hot melt edgebanding machines or manual application with brushes or rollers.

Bond Strength: Evaluate the adhesive’s bond strength to ensure it meets the requirements of your specific application.

Heat Resistance: If the PVC edge banding will be exposed to heat or temperature variations, select an adhesive with excellent heat resistance properties.

Durability: Choose an adhesive that offers long-term durability, with resistance to moisture, chemicals, and everyday wear and tear.

Conclusion:

Selecting the best glue for PVC edge banding is crucial to achieve a secure and seamless bond in your woodworking projects. Whether you opt for hot melt adhesives, solvent-based options, water-based alternatives, or contact adhesives, ensure that the chosen adhesive offers compatibility, strong bond strength, heat resistance, and long-term durability.

By making an informed adhesive selection, you can enhance the overall quality, appearance, and longevity of your PVC edge banded projects, delivering exceptional results that meet the demands of the market.