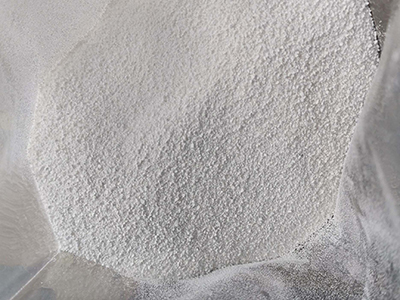

Urea-formaldehyde glue (abbreviation: UF powder) is a polycondensation of urea and formaldehyde under the action of a catalyst (alkaline catalyst or acid catalyst) to form an initial urea-formaldehyde resin, and then under the action of a curing agent or auxiliary agent, it forms an infusible and non-soluble final stage. Resin adhesive.

Urea-formaldehyde resin (UF resin) was first synthesized by B. Tollens in 1844. It was first used after the research of C. Goldschmidt and others around 1896. In 1929, IG company developed a UF resin condensation called KanritLeim and can cure glued wood at room temperature. Intermediates, cause people’s attention.

With the rapid development of science and technology, the new technology of urea-formaldehyde adhesive production technology keeps pace with the times and continues to improve on the basis of the original tradition. As the main raw materials, formaldehyde, urea and winlong are added in a large proportion 20 minutes before acid adjustment. Gum Depot, after adjusting the acid, adjust the PH value to 7-7.5. The urea-formaldehyde adhesive produced by the new technology has good performance indicators, low production cost and reduced free aldehyde content.At the same time meet environmental standards

At present, due to the new technology of urea-formaldehyde glue, which is simple to manufacture, easy to use, low in cost and good in performance, it has become the main type of glue in plywood production, accounting for more than 90% of the glue used in plywood.

Urea-formaldehyde resin adhesive is an amino resin adhesive with good performance, low cost, simple manufacture and wide application. The main application field of urea-formaldehyde resin glue is in the wood processing industry, mainly as an adhesive for particle boards, and as an adhesive in the production of plywood, wooden furniture and joinery. In small quantities it is used in the production of moulding powders, decorative laminates and as a treatment agent for the paper and textile processing industries.