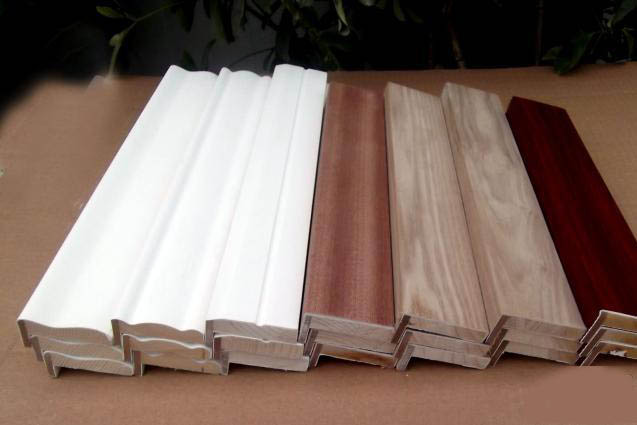

profile wrapping adhesives Product introduction

Benzene-free and aldehyde-free dark black colloid, curing at room temperature, high peel strength and low cost of use, application: suitable for particleboard, MDF board, or PVC of gypsum board, or paper veneer.

How to use profile wrapping adhesives

1. Under normal circumstances, PVC wood grain film is glued on one side, and can be applied by roller coating and scraping.

2. The glue must be uniform and the thickness should be consistent to ensure that there is no lack of glue and no glue accumulation. The thickness of the glue can be adjusted according to the thickness of the film and the weather.

3. The filming time after gluing is recommended to be shorter in summer or autumn when it is dry and high temperature, and it can be appropriately longer in spring and winter when it is humid and low temperature. Touch the glued surface with your fingers and feel it is quick-drying and sticky. Positive static pressure bonding is appropriate. The specific time can only be determined by the customer according to the thickness of the glue, the speed of the strip, the related materials and the ambient temperature.

Note on profile wrapping adhesives

1. The effective shelf life of this product is one year under normal temperature sealing.

2. The unused glue must be covered and sealed to avoid the volatilization of the solvent and the action of the air to thicken and age the glue and affect the quality of the product. The glue that has been opened is best used up within 10 days.

3. When encountering materials that are extremely difficult to bond, the substrate can be surface-treated (using our company’s treatment agent, which does not affect the quality), and then the ideal effect can be achieved by laminating.

4. Do not approach the fire source and keep the production site clean and ventilated.

5. Do not peel off immediately after lamination, so the adhesive layer is not fully cured and does not reflect the strength. It will take 24 hours or longer for the adhesive layer to fully cure, at which point peeling can damage the substrate. The specifics vary depending on the weather and material.

profile wrapping adhesives performance

Good initial adhesion, high bonding strength, short curing time and so on.

Appearance: RY3317 White Emulsion

Solid content: RY3317 56.0-60.0%

Viscosity: (BF RVF 6#/10rpm/27ºC)

RY3317 50000-70000cps

PH value: RY3317 3.0-5.0