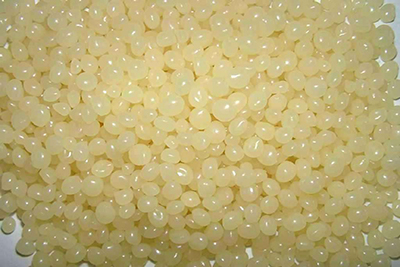

Six-minute gluing method of hot melt adhesive pellets

Hot-melt adhesive pellets are a kind of plastic adhesive product. The physical state of hot-melt adhesive pellets changes with the temperature within a certain temperature range, but the chemical properties remain unchanged. Hot-melt adhesive pellets are non-toxic and tasteless. , How many do you know about the six major gluing methods of hot melt adhesive pellets?

1. Spiral spray glue

This is a more common way of spraying glue. The hot-melt glue is discharged from the nozzle with fine nozzle holes to the regular helical filaments by the external air pressure. Applying glue in this way can greatly reduce the amount of glue used per unit area. Most of the structural adhesives for diapers and sanitary napkins are glued by spiral spraying.

Hot melt adhesive pellets, UL hot melt adhesive stick, hot melt pressure sensitive adhesive

2. Roller coating

The molten hot-melt adhesive is transported into a rotating glue tank, and the upper rubber roller rotates in the glue tank, and the molten hot-melt glue on the upper rubber roller is scraped evenly with a scraper, and the product contacts the rotating rubber roller to be glued evenly. This gluing method is mainly used for fabric coating and compounding, sheet gluing, etc.

3. Flat die head scraping coating

This is one of the more common scraping methods. After the molten hot-melt adhesive passes through the heated throat, it is evenly distributed in the guide channel in the die, and then extruded from the die lip of which the thickness and width of the adhesive film can be preset. Most industrial hot melt adhesive tapes and labels are glued using a die-squeegee process.

4. Foam coating

In some special applications, in order to obtain the function of buffering or shock absorption and reduce the amount of glue used, a special foamable melter can be used to mechanically mix nitrogen into the molten hot melt to form aeration of hot melt adhesive. The hot melt adhesive that has been mechanically foamed is then applied to the workpiece through the nozzle. The foam coating process has been widely used in the assembly of auto parts to replace traditional rubber gaskets.

5. Strip glue

Similar to spot gluing, this process can be used when two substrates only need to be bonded in strips. Common applications are the edges of plastic boxes such as PET curtain boxes, wine bottle boxes and cosmetic boxes.

6. Dotted gluing

Spot gluing is a relatively economical and fast simple process when two objects only need to be joined in part. Spot gluing is commonly used for folding carton or cardboard binding.

Winlong hot melt adhesive manufacturers have 25 years of industry experience and a strong R&D team. The price of our products is very advantageous, and the quality is trustworthy