How to judge whether the hot melt adhesive purchased is environmentally friendly?

At present, the function and application of adhesives have received extensive attention, but the environmental protection issues of adhesives are often easily overlooked. Whether environmental protection has become a bottleneck for the further development of adhesives, and solving the problem of environmental pollution has become a top priority.

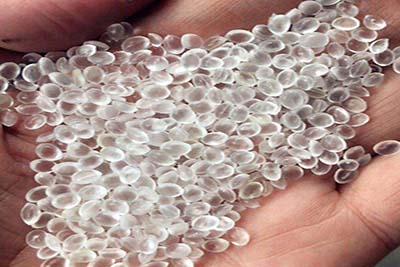

Hot melt adhesive is a kind of polymer material such as: EVA, rubber, polyolefin, polyamide, etc. as the main material, with tackifying resin and softener, etc., produced. Solvent-free and non-volatile. Compared with solvent-based, oil-based, and water-based adhesives, hot melt adhesives are more environmentally friendly.

However, the layers in the hot melt adhesive are very different. From the environmental protection requirements of the European Union and the United States, many hot melt adhesives currently on the market do not meet the standards. In order to reduce costs, many hot melt adhesive companies use a lot of cheap materials that are not environmentally friendly, and the hot melt adhesives produced by them are identified as non-environmental products.

How can we distinguish whether the hot melt adhesive we buy is environmentally friendly? At present, the international environmental protection test items for hot melt adhesives include ROSH standard, formaldehyde test, 18 polycyclic aromatic hydrocarbons, halogen-fluorine, chlorine, bromine, iodine content determination, total para-octane flavanyl compound (PFOS) content determination, nonyl Determination of phenolic polyvinyl chloride ether (NDEOS) content, and REACH84 tests, etc. Medical hot melt adhesives are also tested for skin non-sensitization.

Winlong glue manufacturers have all passed environmental protection testing, 25 years of professional hot melt adhesive manufacturers, quality is guaranteed